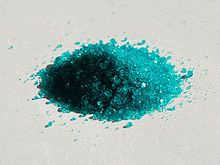

One of the best ways to ensure that a product lasts for a long time in industry is to give it a coating of Nickel. Nickel, and the many Nickel Composites that we glean from the metal, can be used in a variety of ways. However, in terms of electroplating and coatings, such as that undertaken by a company like https://www.poeton.co.uk/advanced-treatments/apticote-460-nickel-composites, it is the second variant, Nickel (II) sulfate, that is the best. Here the addition of sulfuric acid and hexa – heptahydrates creates the perfect substance for electroplating.

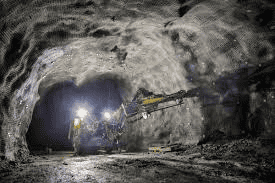

Why do we electroplate with Nickel Composites? The answer is simple. Nickel is expensive to mine and to find geologically. Therefore we cannot use it in vast quantities otherwise it would be fair to say that most metallic objects would be made from it. However, to balance this cost is the consideration that Nickel is extremely rust and tarnish resistant. Therefore if you have a product that is going to be exposed to all winds, weathers and elements you need something that can resist them.

The act of electroplating a thin layer of Nickel around the subject can give it decades of life without needing to be replaced. This also reduces the amount of Nickel needed to be mined as well.