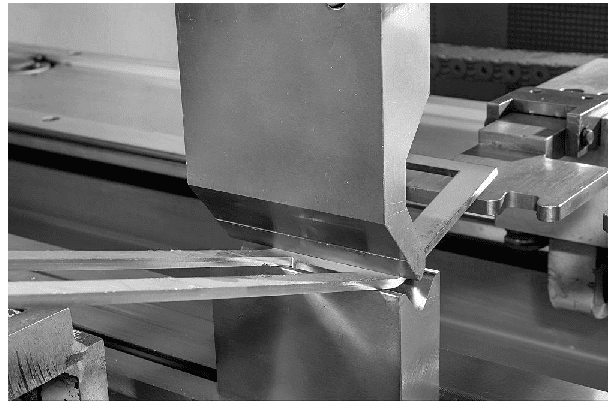

The practice of bending materials such as metals is used across many industries. There are many reasons for doing this and many methods. The vast majority of methods involve the use of bending machines, of which there are several types.

Mechanical bending machines

Mechanical bending machines can bend metal and other materials into specific shapes. As they do not use a stationary die, the materials can be bent to exact specifications and precise shapes. They use a motor that rotates a flywheel and is controlled by a clutch.

Hydraulic bending machines

Hydraulic bending machines are automated and used to form/shape/bend materials, which are usually metals. They consist of a workbench, a support, a clamping plate, and a pressure plate. The clamp can be controlled automatically or manually. The machine also has a movable coil that is energised via a hydraulic cylinder, generating the required force.

Hydraulic bending machines are flexible, inexpensive and portable when compared to more conventional bending machines. They can handle both small and large pipes. They are used across industries such as chemical, production, and automotive. One of the most common mechanical bending machines is the hydraulic press brake.

Advantages of bending machines

Bending machines have lots of advantages, including being cost-effective, efficient, safe, flexible, precise, and low maintenance.

Potential solutions

If you feel that bending machines could be useful for your business/situation, there are many specialist companies that can help. Many of these firms have significant online resources that may prove useful, such as www.cotswold-machinery-sales.co.uk/euromac-bending-machines/horizontal-bending-machines/. Euromac bending machines are some of the most popular around.

CNC bending machines

Computer numerically controlled (CNC) bending is a modern method that uses computers to produce a highly accurate set of instructions. These instructions are then sent to a specialist bending machine that positions the sheet of material as required and then bends and moves the material as needed.

Using CNC bending machines can create precise and exact shapes, including cones, coils, tubes, and small parts. It keeps waste to an absolute minimum, as it uses only the optimum amount of material.