There are two types of people – those who want a solution that works and those that jump on trends. On one side, you have people that still use a lathe, drill press or even manual tapping equipment. These traditional methods will get the job done, but repeatability and quality are not guaranteed. On the other side, there are people who pull the trigger on the newest tapping tools. All these options will still work 200 years down the line, but later versions are clearly better.

Today’s focus is on the newer tapping equipment. Here’s everything you need to know.

How Does an Electric Tapping Machine Work?

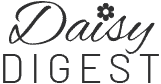

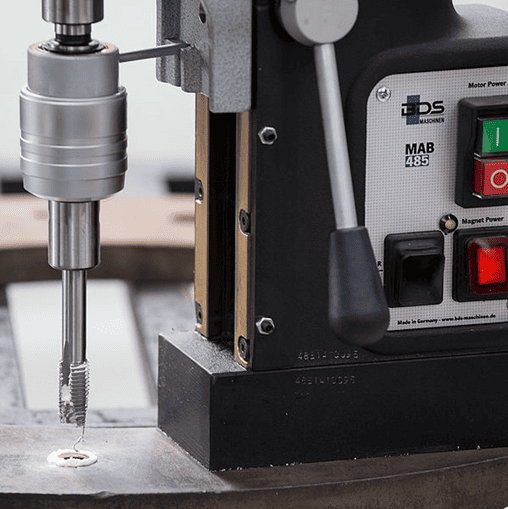

Generally speaking, an electric tapping tool is a fancy servo motor attached to a tilting arm. This flexible attachment allows multi-angle tapping. And every joint comes with a control mechanism, so you can manipulate the setup at will. This arm usually sits on a height-adjustable base with the option to screw or secure it with a clamp.

Most tapping machines will have an electronic box casing for speed regulation. That allows users to control the clockwise and anticlockwise motor rotation. Newer models also have a depth sensor that disengages the motor. This feature works even when the operator is still holding the power button.

The E-Tiger electric arm, for example, features even more bells and whistles. It comes packing a 220V high-frequency motor with an option to get a 110V variant. The head assembly on this machine allows four 90-degree positions along with horizontal and vertical taps. On top of that, it also has an optional automatic thread lubrication system. This Roscamart product is available in online stores such as https://www.cotswold-machinery-sales.co.uk/roscamat/.

What Is the Difference Between Electric and Pneumatic Tapping Tools?

Well, the main difference is how these two machines power their motors. Pneumatic devices use older tech that drives the motor using high-pressure air, while electric tappers use servo motors. The compressed air goes into the motor through the air pressure regulator, driving the motor in the desired direction.

The only major problem with this setup is power regulation. The working pressure needs adjustment depending on the material and size of the tap, which is not an exact science. Still, most of these devices come with an overload protection device. This optional circuit shuts down the motor if something goes wrong.